See also

Freedom Series - Wrap Around Case Packer

Minimum Case Size: 6 x 6 x 7.25 in.

Maximum Case Size: 18 x 14 x 19 in.

Astro Packaging Freedom Series Wrap Around Case Packer

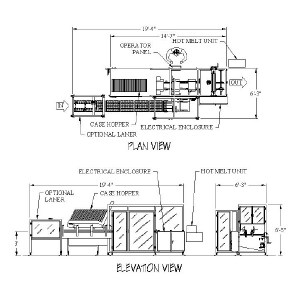

Astro Packaging's FREEDOM SERIES™ Wrap Around Case Packer is designed with your floor space and production environment in mind. The machine is built to make case size changeover an easy process while its small size makes it a comfortable fit on your production floor. The Freedom Series wrap around case packer can run up to 35 cases per minute maximum line speed.

The wrap around case packer is constructed on a 2 x 2 x 3/16” wall tube steel frame. The open design makes access to internal components easy. The case path through the machine has an angled pan at the bottom of the frame so any items that fall through slide to the operator side for easy retrieval. All product contact parts are stainless steel, plated or an approved plastic. The Freedom Series wrap around case packer is so versatile that it can be changed over from packing cases to packing trays without modification.

Operation of the Freedom Series wrap around case packer is simple. A wrap around shipper is pulled off the case hopper via vacuum, opened into a “J” shape, and placed onto the flight chains where four opposed “flight lugs” hold the cases in place. The erected case is forwarded to the packing station where it waits for a product group. Product is accumulated into its proper pack patter and then pushed into the waiting empty case. The case is moved to the gluing station where hot melt glue is applied to the manufacture joint by a “flying” glue head. The case moves again to the closing station while opposed hot melt glue heads apply hot melt to the ends of the case. When the case comes to a stop the entire case is squared and flaps are closed and sealed. The case discharges onto your conveyor straight out the back of the machine (no change of case path is necessary.)

Standard Features of the Freedom Series Wrap Around Case Packer

- Power coated 2 x 2 x 3/16” wall steel frame (medium gray.)

- Angled pan below case path for ease of part retrieval by operator.

- Stainless steel, plated, and/or approved plastic contact parts to product.

- Sensorless vector drive/Inverter duty motor for smooth and consistent case transport.

- Programmable logic control.

- Color operator interface.

- Ethernet IP communication.

- NEMA 12 wiring with 24 Volt DC controls.

- Guarding with monitored safety circuit.

- Speeds up to 35 cases per minute.

- Changeover to trays without modification.

- Hot melt case sealing.

- Non‐lube service pneumatic components.

- 480 Volts AC 3‐phase 20 amp main supply (other voltages are available.)

- Quick and easy changeover to meet your production schedule.

- A cost effective solution.

- Small footprint.

Optional Features of the Freedom Series Wrap Around Case Packer

- Single lane or multi-lane for variety pack packaging.

- Line combining.

- Product/case re‐orientation.

- Pad insertion.

- Configured to pack RSC boxes

- Stainless steel construction with NEMA 4X electrical.

Contact Astro Packaging and allow us to show you how the FREEDOM SERIES™ wrap around case packer can be the solution to your case packing needs.